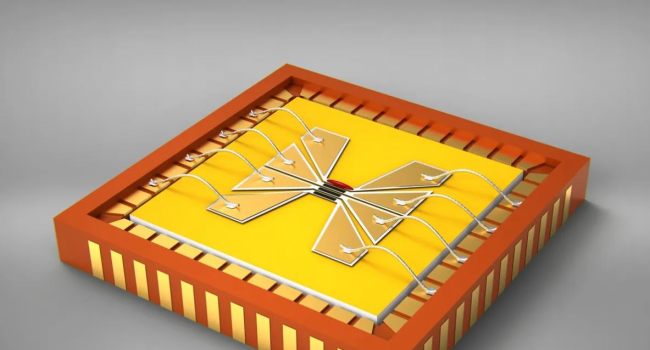

Newly developed ultra-thin display with metasurface is faster and more energy-efficient than LCD display, and could change the entire industry

Australian scientists engaged in research in the field of optical metamaterials have created an ultra-thin screen with a metasurface, which is faster, saves more energy than LCD screens and can lead to radical changes in this area, IEEE Spectrum reports.

A prototype four-pixel display at less than 5 volts can transmit a certain amount of visible and near-infrared light in just 625 microseconds, which, net of other factors, corresponds to 1,600 frames per second. In other words, the frame rate of this technology is more than three times that of today's fastest displays.

The magazine notes that recent research in this area could lay the foundation for the creation of next-generation screens that are about a hundred times thinner than a human hair, but provide 10 times better resolution and consume half as much electricity as LCDs.

Characteristics of metasurfaces

Metasurfaces have properties not normally found in nature, such as the ability to refract light in unexpected ways. Researches into metasurfaces and other metamaterials are creating coatings that can shield objects from light, sound, heat, and other types of waves. Optical metamaterials designed to manipulate light contain structures with repeating patterns that are smaller than the wavelength of the light affecting them. However, these structures are usually static, and this has been a major obstacle to the creation of devices requiring optically variable properties, such as displays.

Scientists have tested electrically tunable metasurfaces that can be produced using already existing CMOS sensor output technology. The principle of operation is based on the thermo-optic effect of silicon, which, depending on the temperature, transmits light differently.The device consists of a silicon metasurface, specifically a 155-nanometer-thick film with holes 78 to 101 nm in diameter arranged in a certain order. The metasurface includes 380-nanometer-thick transparent conductive layers of indium and tin oxide that act as electrical local heaters.

Another important advantage of the new technology is its stability. "Silicon nanostructures are known for their durability, which is one of the reasons they remain the most popular material in the microchip industry today," said study co-author and professor of physics at the Australian National University (Canberra) Dragomir Neshev. "We have been testing our prototypes for several months and have not noticed any degradation."

"And the main problem that still needs to be solved is the low cooling rate that's visible to the naked eye. The cooling effect can be significantly increased with additional solutions such as active cooling or air waves around the pixels,” said Dragomir Neshev.

The future of metasurfaces

The authors of the study claim that the new metasurfaces can replace the liquid crystal layer of LCDs. Additionally, they don't need polarizing filters, which are responsible for half of the light intensity and power used in LCDs.Existing LCD production lines can be upgraded with minimal modifications to replace liquid crystal pixels with metasurface pixels.There is no need to invest significantly in new pipelines to integrate this technology. Since LCD manufacturers have spent more than $100 billion on existing factories, they may be interested in this new technology to give their factories a second life.

In hopes of entering the display market, the researchers now intend to optimize the device's specifications (power consumption, cooling, etc.). In addition, they hope that artificial intelligence and machine learning techniques can help develop thinner and more efficient metasurface displays.

The researchers plan to develop a large-scale prototype of this technology that can create images within the next five years, and the integration of this technology into real devices is possible within the next 10 years.

- Related News

- James Webb captures never-before-seen details of Horsehead Nebula (photos)

- The end of the Universe: 3 plausible theories of a global apocalypse

- 4 flares erupted from Sun in rare event: the Earth may be hit by geomagnetic storm (video)

- 11 incredible satellite photos published on Earth Day

- Scientists create optical-mechanical quantum memory that can become basis of quantum Internet

- The water found on Moon is enough for about 1 million people - Vladimir Surdin

- Most read

month

week

day

- Alphabet will pay dividends for the first time in its history 863

- Google is developing a budget smartwatch 821

- Large taxpayers of Armenia’s IT sector: What changes have taken place in 2024 Q1? 778

- Digital Julfa Network is launching a pan-Armenian centre in the metaverse, on the Fastexverse virtual platform 776

- Insider shows mockups of all 4 iPhone 16 models 723

- Sparkles: Boston Dynamics unveils a furry robot dog that can dance (video) 700

- 8800 mAh battery, 2.4K IPS screen, thermal imager: Blackview has introduced a new ultra-durable smartphone 692

- Smartphone catches fire in child's hand in Russia 626

- Xiaomi unveils exclusive Redmi Note 13 Pro+ dedicated to Messi and Argentina national team 625

- Is there a ninth planet in the solar system? Scientists find new evidence 619

- Archive